Abstract

The key direction of industrial development is the transition to the concept of "Industry 4.0", the implementation of which has significant difficulties in Russia due to the backward production infrastructure of plants in most industries. At the same time, the level of readiness for such a transition for each industry may be different. The purpose of the article is to identify preliminary guidelines for the development policy for various industries in Russia within the framework of the concept of "Industry 4.0". The object of the study is the manufacturing sectors of Russia. The subject of the research is the tools of the "Industry 4.0" concept. The methods of descriptive statistics are used in this article. The cluster analysis was carried out and the Cobb-Douglas production function was constructed. A set of management actions has been developed using the tools of the "Industry 4.0" concept for different groups of production sectors. The proposed recommendations can be used to improve the policy of modernization of the industrial infrastructure of Russia.

Keywords: Industry 40, digitalization, Cobb-Douglas production function, environmental efficiency, innovation

Introduction

The Fourth Industrial Revolution or "Industry 4.0" was originally a concept that was aimed at improving the technological efficiency of industry. The concept is based on the creation of cyber-physical systems, which are the integration of all production processes via the Internet and systems are independently carrying out the production activities, making adjustments to management and planning actions. Digitalization extends to the entire life cycle of production, including design development, production samples, production management, planning and optimization, as well as adjustments to production activities taking into account the market dynamics and changing the needs of consumers. The digital architecture of production systems can be implemented in enterprises of all types of activities, independently of the type of production capacity. Therefore, "Industry 4.0" can be implemented in completely new production facilities and there can also be a gradual modernization of existing industrial enterprises and production facilities.

Problem Statement

The acceleration of digital development can be achieved through the implementation of appropriate public policies. To increase the address capacity, it is essential to determine the level of industrial development of industries with the identification of patterns of their development.

Research Questions

The revolution of the concept of "Industry 4.0", the possibility of its implementation on the examples of industrial enterprises, the creation of smart production, the definition of key technologies and the architecture of the production information system are among the research interests of Almada-Lobo (2016); Chen et al. (2017); Li et al. (2017); Liu and Xu (2017); Theorin et al. (2017). The problems of implementing modern information and cloud technologies in production activities, their comparison and an overview of the possibilities are given in the works of Georgakopoulos et al. (2016); Lu (2017); Pereira and Romero (2017). The need for digitalization of the supply chain for the effective development of production systems is justified in the works of Pfohl et al. (2015); Shinkevich et al. (2018). Innovative development of industrial production within the framework of the concept of sustainable development, with an emphasis on improving environmental efficiency and safety is reflected in the articles of Lubnina et al. (2018); Melnik et al. (2016); Shkarupeta et al. (2020). Innovative technologies, tools that are aimed at energy and resource conservation of production activities are proposed in the works of Akhmetova et al. (2020); Balzamov et al. (2019). Nowadays, the development of industrial production within the framework of the concept of "Industry 4.0" is a popular topic of research, but the identification of the specifics of tools for various types of production in the literature is poorly covered, which caused the relevance of the chosen research topic.

Purpose of the Study

The purpose of the study is to determine the preliminary guidelines for the formation and implementation of the state policy for the development of industrial sectors in Russia within the framework of the "Industry 4.0" concept.

Research Methods

The article uses the methods of descriptive statistics to analyze the indicators "Production volume, million rubles" and "Production index, %" in the context of types of production in Russia in 2018.

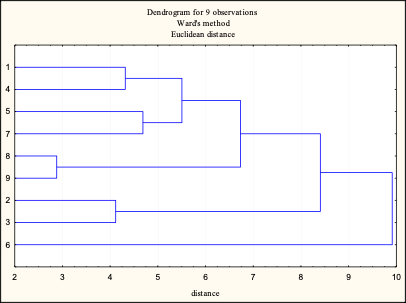

Using the dendrogram of the grouping of large types of production activities (Ward method), two groups of industries are identified according to their level of development within the framework of the "Industry 4.0" concept.

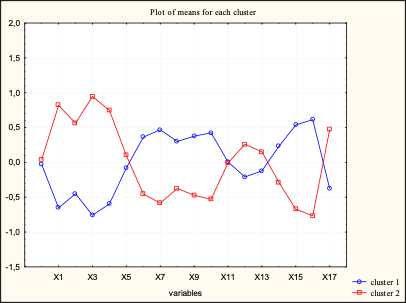

The graph of the average values for each cluster allowed to determine the strengths and weaknesses of the production development of different groups of industries.

To identify the degree of dependence of the volume of production on the factors that create it, the Cobb-Douglas production function is constructed, the results of which are used to specify the control effect on the development of the Russian production sector.

To achieve the main target of the study – to determine the preliminary guidelines for the formation and implementation of the state policy for the development of industrial sectors in Russia within the framework of the Industry 4.0 concept, it is important to assess their development.

The solution of this problem is based on the distribution of various types of production into groups using cluster analysis tools. The study was conducted on the following range of enlarged types of production:

- food production;

- wood production;

- paper production;

- chemical production;

- production of mineral products;

- metal production;

- machinery manufacturing;

- electrical equipment manufacturing;

- transport production.

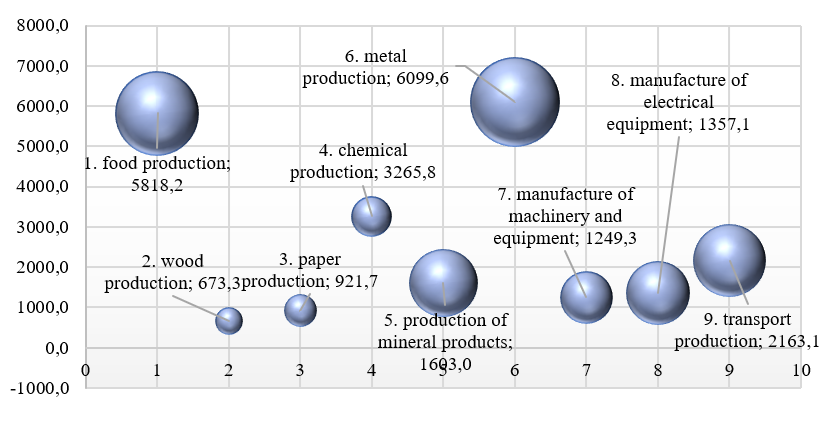

The development of industrial sectors in terms of production volume was assessed. The largest volumes of output among the studied types of production in 2018 were produced by enterprises of "production of metal products" for a total amount of 6099,6 million rubles, which is 26,3% of the total volume of shipped goods of the industrial complex, in second place in this indicator are enterprises of food production – 5818,2 million rubles or 25,1% (Figure 1). The lowest production volumes are accounted for by enterprises of " wood production", which accounted for 2,9% of total output or 673,3 million rubles, and "paper production" – 921 million rubles (3,9%).

Findings

The level of development of industrial sectors is difficultly to assess based only on the indicators of production volumes. Since the concept of "Industry 4.0" prioritizes the digital development of production, the introduction of the modern technologies that can increase the profitability of enterprises by reducing the negative impact on the environment, saving energy and resources, the following components were identified for the cluster analysis:

Y – the production volume, million rubles;

X1 – the share of innovation, %;

X2 - implemented innovations, million rubles;

X3 – the number of innovative technologies that were used, units;

X4 – the number of innovative technologies that were purchased, units;

X5 - the innovation costs, million rubles;

X6 - the emissions to the atmosphere, thousand tons;

X7 - the neutralization of emissions into the atmosphere, thousands of tons;

X8 - the disposal of industrial waste, million tons;

X9 - the investments for the implementation of environmental measures, million rubles;

X10 - the current costs for the implementation of environmental measures, million rubles;

X11 - the coefficient of renewal of FA (fixed assets), %;

X12 - the retirement ratio of FA, %;

X13 - the wear level of FA, %;

X14 - the investments in fixed assets, billion rubles;

X15 - the production index, in % of the previous year;

X16 - the profitability, %;

X17 – the level of innovation activity of organizations, %.

In order to identify groups of enterprises by level of development within the framework of the "Industry 4.0" concept, a dendrogram of the distribution of industries into clusters is constructed using the Ward method, which is based on the use of the average values of variables within the cluster and the average values of variables that are attached to it (Figure 2). The graphical representation of the results of this method allows to conclude that the entire set of observations on the level of development can be divided into two clusters. The first cluster includes wood production, paper production, chemical production, mineral production and metal production. The second cluster is represented by food production, machinery manufacturing, electrical equipment manufacturing, transport production.

For the convenience of interpreting the results of the cluster analysis by the K-means method, the graph of the average values for each cluster was constructed (Figure 3), according to which the following generalizations can be made. The strength of the enterprises of the first cluster is a relatively low negative impact on the environment, high environmental safety. However, the enterprises of these industries have a backward production infrastructure that requires modernization, automation and digitalization. The enterprises included in the second cluster are characterized by the tendency to introduce innovative industrial technologies, improve the production and increase production volumes. At the same time, these types of production are quite energy- and resource-intensive and, consequently, less environmentally efficient.

Plotting the average values for each cluster also allowed to identify indicators that have a strong negative impact on the enterprises included in each cluster. To improve the management of these groups of sectors, the Cobb-Douglas production function was constructed for each cluster. This function allows to identify the dependence of the volume of production on the factors that create it and labour costs (Table 2).

The results obtained allow to make the following recommendations for improving the efficiency of the development of various industrial sectors within the framework of the "Industry 4.0" concept. Limited natural resources and international environmental safety requirements are an obstacle to development for the industries included in the first cluster. The impact of production on the environment can be expressed in the consumption of large amounts of natural resources, the negative impact on the environment, the vast territories occupied by production, the formation of large volumes of waste. The creation of environmentally friendly smart enterprises is primarily based on online monitoring of possible scenarios of industrial disasters, emissions, energy consumption, etc. Online monitoring allows to keep track of the parameters of the operational level, production processes, auxiliary and service industries, the economic and financial system. In addition to the organization of online monitoring, ensuring environmental safety requires the modernization of the engineering infrastructure of the enterprise, the cable system, the waterwaste treatment system, the waste management system, the energy system, etc. Reducing the negative impact on the environment depends on the introduction of resource-saving production technologies and automation will reduce the number of personnel working in harmful working conditions.

Among the key technologies of Industry 4.0, that are important for the development of manufacturing industries, which are included in the second cluster, the following can be distinguished. Introduction of the industrial Internet of things, which allows to integrate devices, machines, equipment and people into a single information system. Fast and cost-effective collection, storage and security of big data expands the capabilities of predictive and advanced analytics at different levels of the production capacity of company. The introduction of machine learning technologies allows to conduct deep analysis using neural networks, improve the capabilities of algorithms for managing the production processes of the enterprise. Automation and robotics make production more efficient and safer, and by providing high accuracy and mobility, robots release staff time from routine work, allowing them to focus on other non-repetitive or important tasks.

Conclusion

The concept of "Industry 4.0" is characterized by the creation of smart factories, smart industries, through the creation of "cyber-physical systems". Production systems are integrated into a single network which are capable to work in real time, self-tune, reduce the number of production errors and downtime, interact with manufactured goods and independently adapt to new market requirements completely offline, i.e. without human intervention. The advantages of such an organization of production are ensuring the information transparency and creating a virtual copy of the physical world, providing the technical support for human activities in the field of working with big data and performing a number of unsafe works for humans. The article identifies groups of industries by the level of industrial development and control actions for each cluster within the framework of the "Industry 4.0" concept were suggested. The proposed recommendations can be used to improve the industrial infrastructure of Russia in accordance with modern global trends.

References

Akhmetova, I., Balzamova, E., Bronskaya, V., Balzamov, D., Lapin, K., & Kharitonova, O. (2020). Selection of the optimal type of thermal insulation structure based on the neural network modelling. E3S Web of Conferences, 216, 01037.

Almada-Lobo, F. (2016). The Industry 4 revolution and the Future of Manufacturing Execution Systems. Journal of Innovation Management, 3(4), 17.

Balzamov, D. S., Akhmetova, I. G., Balzamova, E. Y., Oykina, G. I., & Bronsrkaya, V. V. (2019). Options for organizing own sources of energy supply at the facilities of generating companies based on steam screw machines. Journal of Physics: Conference Series, 1399(5), 055018.

Chen, B., Wan, J., Shu, L., Li, P., Mukherjee, M., & Yin, B. (2017). Smart factory of Industry 4.0: key technologies, application case, and challenges. IEEE Access, 6, 6506-6519.

Georgakopoulos, D., Jayaraman, P. P., Fazia, M., Villari, M., & Ranjan, R. (2016). Internet of things and edge cloud computing roadmap for manufacturing. IEEE Cloud Comput, 3(4), 66-73.

Li, X., Li, D., Wan, J., Vasilakos, A. V., Lai, C.F., & Wang, S. (2017). A review of industrial wireless networks in the context of Industry 4.0. Wireless Networks, 23(1), 23-41.

Liu, Y., & Xu, X. (2017). Industry 4.0 and cloud manufacturing: a comparative analysis. Journal of Manufacturing Science and Engineering, 139(3), 034701.

Lu, Y. (2017). Industry 4.0: A survey on technologies, applications and open research issues. Journal of Industrial Information Integration, 6, 1-10.

Lubnina, A. A., Shinkevich, M. V., Yalunina, E. N., Savderova, A. F., & Komissarova, M. A. (2018). Innovative strategy for improving the efficiency of industrial enterprises management. Espacios, 39(9), 25.

Melnik, A. N., Lubnina, A. A., & Smolyagina, M. V. (2016). On modelling of different sectors of economy in terms of sustainable development. International Business Management, 10(23), 5592-5595.

Pereira, A. C., & Romero, F. A. (2017). Review of the meanings and the implications of the Industry 4.0 concept. Procedia Manuf, 13, 1206-1214.

Pfohl, H. C., Yahsi, B., & Kurnaz, T. (2015). The impact of Industry 4.0 on the supply chain. In: Innovations and strategies for logistics and supply chains: technologies, business models and risk management. Proceedings of the Hamburg international conference of logistics (HICL), 20. 31-58. Berlin.

Shinkevich, A. I., Kudryavtseva, S. S., Simaeva, E. P., Stolyarova, A. N., Kharisova, G. M., & Petrova, E. V. (2018). Transport and communication space development in open innovation model. Espacios, 39(9), 27-36.

Shkarupeta, E., Savon, D., Safronov, A., Avlasenko, L., & Kruzhkova, G. (2020). Digital Ecosystem Development Based on Open Innovation Model. Russian Conference on Digital Economy and Knowledge Management, 601-605.

Theorin, A., Bengtsson, K., Provost, J., Lieder, M., Johnsson, C., Lundholm, T., & Lennartson, B. (2017). An event-driven manufacturing information system architecture for Industry 4.0. International Journal of Production Research, 55(5), 1297-1311.

Copyright information

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

About this article

Publication Date

25 September 2021

Article Doi

eBook ISBN

978-1-80296-115-7

Publisher

European Publisher

Volume

116

Print ISBN (optional)

-

Edition Number

1st Edition

Pages

1-2895

Subjects

Economics, social trends, sustainability, modern society, behavioural sciences, education

Cite this article as:

Lubnina, A. A., Garipova, G. R., Bronskaya, V. V., Shaikhetdinova, R. S., Balzamov, D. S., & Kharitonova, O. S. (2021). Development Of Russia Manufacturing Sectors Within The Framework Of "Industry 4.0". In I. V. Kovalev, A. A. Voroshilova, & A. S. Budagov (Eds.), Economic and Social Trends for Sustainability of Modern Society (ICEST-II 2021), vol 116. European Proceedings of Social and Behavioural Sciences (pp. 493-501). European Publisher. https://doi.org/10.15405/epsbs.2021.09.02.55