Abstract

The importance of research methodology is substantiated by the relevance of efficient production hi-tech development (HTD) management stability. The multidisciplinary application of educational, research, investment and techno-technological resources of a complementary type were suggested as a method to find a compromise between the aims of efficiency and innovativeness. The method supplements the management theory with changes based on the combination of methodological tools of production high-tech development model «4D CR» with regulators of enterprise innovative competences in the innovation diffusion model by Everett Rogers. An algorithmic scheme for developing and functioning the mechanism for managing enterprise high-tech development was suggested to implement processes of resource integration and method combination. The research's goal is to substantiate the necessity to develop the theory of management based on spatiotemporal and convergence and integration methodology of control to improve the efficiency of developing high-tech industrial production. It was found that the convergence approach to the integration of resources and combining methods enables to widen the range of management methods to engineer and develop high-tech industrial production. It provides the system's integrity and retains its organizational behavior parameters within the frame of possible changes in the high-tech development efficiency trajectory.

Keywords:

Introduction

The importance of research methodology is substantiated by the relevance of efficient production hi-tech development (HTD) management stability. The multidisciplinary application of educational, research, investment and techno-technological resources of a complementary type was suggested as a method to find a compromise between the aims of efficiency and innovativeness. The method supplements the management theory with changes based on the combination of methodological tools of production high-tech development model «4D CR» with regulators of enterprise innovative competences in the innovation diffusion model by Everett Rogers. An algorithmic scheme for developing and functioning the mechanism for managing enterprise high-tech development was suggested to implement resource integration and method combinations.

Problem Statement

The notions need to be supplemented by the innovations' properties expanded diffusion in the regions and nationwide. The new industrial revolution factors, which show the necessity of science-based multidisciplinary convergence in generating digital platforms, should be considered. The resource integration in education areas, scientific research developing and designing high technologies and hi-tech industrial enterprises' resources make it possible. A new paradigm of advanced production substantiates the management theory development approach based on the spatiotemporal integration of resources for high-tech object transformations in units of different types and scales.

Research Questions

Research issues deal with the development of spatiotemporal and convergence and integration methodology of control over the industrial enterprise innovation transformations according to high-tech development efficiency and innovativeness.

Purpose of the Study

The research aims to substantiate the necessity to develop the theory of management based on spatiotemporal and convergence and integration methodology of control to improve the efficiency of developing high-tech industrial production.

Research Methods

According to the high-tech development efficiency indicators, the spatiotemporal and integration-convergence methodology to control the enterprise transformations is at the core of the study. The method of combining high-tech production development model «4D CR» with tools of enterprise innovative development competences, qualitative expert assessment, matching method, and consistent taxonomy method was used.

Findings

The research proves that the enterprise transformations based on resource integration are efficient due to applying specific strategic management intangible assets. The development of the spatiotemporal integrative model «4D CR» for key resources integration for industrial production high-tech development efficiency improvement and combination with the tools of enterprise innovative competences model in innovation diffusion Everett Rogers has become the theoretical finding.

The innovation development management theory is supplemented by the method that controls the processes of «4D CR» tool modeling with the regulators of competence types for enterprises in Everett Rogers's innovation diffusion model (Rogers, 1983). It is substantiated that methods should use the general and specific management functions identified according to the corresponding stage of high-tech development. They provide control over the resources integration scale with the enterprise competence regulators and the institutions that are the resources' owners. The scale is determined by the strategic management goals at each level.

The research proves that minimal resource and competence integration when essential management functions applied is enough to implement modernization processes. The practicability of combining «4D CR» models with the regulators of competences in the Everett Rogers's innovation diffusion model is stated. It boosts enterprise high-tech transformations' efficiency, which is necessary to create technological breakthrough conditions when launching each new high-tech innovation product.

Combining and integrating processes are carried out in evolutionary and leaping processes based on the theory of system convergency and integration of complementary resources. The variety of theoretical and methodological approaches to the management of high-tech integration processes exacerbates the choice when the efficiency of generating and developing processes of hi-tech industrial production is concerned. That's why the method of qualitative assessment to set a multidisciplinary and cross-branch management tool seems attractive.

We revealed high peer reviews while applying complementary educational, research, investment and techno-technological resources as a whole. The resources correspond to poly-resource management methodology for the control of generating and developing hich-tech industrial processes (Alabugin et al., 2016). The reviews state the necessity of spatiotemporal integration of resources with the help of enterprise innovation management improvement according to the high-tech development efficiency indicators of the derating criterion of their disbalance with innovativeness and competitiveness of the products.

The system HTD efficiency management methodology is defined as spatiotemporal and convergent-integrative as it generates and controls structures of integrative mechanism with the viewpoint of system convergence, models, and management methods. Complementarity of resources provides long-term development with a special set of general and specific functions that influence the quality and efficiency of management. The functions are included in an integrative mechanism of resource integration management and management methods combination (abbreviated - MRIMMMC). The mechanism provides the engineering of the functioning processes by compromising efficiency targets and innovativeness. It is stated that the convergent approach to integration or combination of diversified complementary (educational, investment, research, techno-technological) resources enables to widen the range of management methods. Organization and development of high-tech industrial production ensure system integrity and convergence of high-tech development efficiency and innovativeness trajectory.

The introduction of the integrative mechanism of resource integration management and management methods combination into the digital platform of the spatiotemporal resource integration is substantiated, allowing us to consider the mechanism as a digital twin (Borovkov et al., 2018; Borovkov et al., 2019; Tao, 2018; West & Blackburn, 2017) of the high-tech industrial production management system. The mechanism becomes a simulator modeling the high-tech development processes and aiming to achieve the project's high-tech parameters. Such interaction provides the client with resource complementarity, which corresponds to the matrix of target indicators and technological and production constraints suggested in a lot of researches (Borovkov et al., 2018; Borovkov et al., 2019). As this approach demands the unique theoretical methods of quality assessment for diversifying high-tech industrial production efficiency management, we consider it necessary to specify factors and identify the methodological principles of generating and developing the high-tech industrial production.

We suggest the spatiotemporal model «4D CR» of key resources integration of production high-tech development efficiency improvement. Author's techno-economic paradigm of high-tech industrial production development, process approaches, synergetic analysis theories, the theory of functional and structural, evolutional and revolutionary changes (Alabugin et al., 2016; Andersen et al., 1989; Baev, 1992; Zang, 1999) provide the scientific and theoretical basis of the methodology under discussion. The notions from these theories enabled to substantiate the idea of their development in the context of the integrative poly-resource high-tech industrial production efficiency management based on the cyclic process model while leveling disbalance between efficiency and result innovativeness. Its structural elements are described in the early discussed concept and theoretical model of theory development (Alabugin & Beregovaya, 2017).

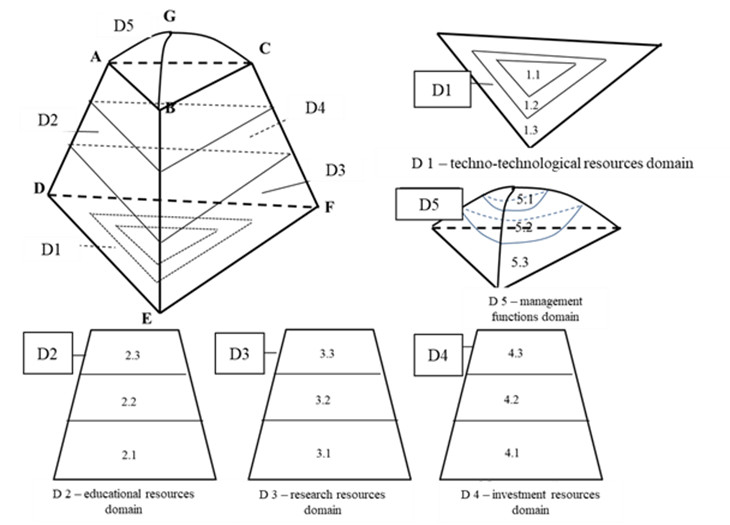

The essence of the integrative model of poly-resource method combination for improvement of high-tech industrial enterprise development efficient management quality in the long-term period is revealed. The spatial and comprehensive nature of the «4D CR» model (integration of 4D complex resources (educational, research, investment and techno-technological) in space demonstrates that diversified processes of management improvement focus on consistency of 4 directions (4D) that is the comprehensive use of educational, research, investment and techno-technological resources (CR) of high-tech development (Figure

The comprehensive representation of the determinants, their interrelations and ability to assess the importance of the educational research, investment and techno-technological resources for the efficiency improvement of high-tech industrial production development enabled to work out the tasks (level 1), methods (level 2) and results (level 3) of the sub-systems domains as well as functions of the integrative mechanism in details.

The model «4D СR» is represented as a space-oriented graph. The model consists of five determinant (D) domains: D 1 – techno-technological resources domain; D 2 – educational resources domain; D 3 – research resources domain; D 4 – investment resources domain; D 5 – management functions domain. The model considers the comprehensive and complementary impact on the functioning performance of the management mechanism of resource integration and combination of management methods to control high-tech development.

The techno-technological resources determinant domain is identified as a basis for the use of the integrated resource combination as well as a result of the resource integration. Besides D 1 is the source of the technological industrial constraints which are considered when organizing high-tech industrial production. The development process in different time periods may reach the corresponding stage and acquire a certain type and stage (competitive modernization, low-, medium- or high-technological level of production) using the combination of integrated resources: it depends on the amount of capital assets which determine the choice of the technology. The collaborative effect of the whole resource combination (techno-technological, educational, research and investment) encourages upgraded technologies. The digital platforms facilitate the transition to a new technological paradigm within the concept of "Industry 4.0" (Plotnikov, 2018; Tarasov, 2018; Tolstykh et al., 2018).

The task (1.1), method (1.2) and result (1.3) levels are emphasized in the techno-technological resources (D1) domain. The task level (1.1) is represented by the necessity to create fixed assets to organize diversified processes of generating and developing the high-tech industrial enterprise. To carry out the task 1.1 the economic, socio-psychological, statistic methods of quality management (Berezansky & Chulkov, 2017; Smirnova & Erokhina, 2019), as well as methods of lean production, are to be applied (Shibanov, 2019). These methods promote rational job management at the manufactured stage of technological development. The determinant effect (level 1.3) at the first stage is the elimination of time and raw material waste, which will encourage production efficiency improvement and generate the ground for high-tech development. In the course of integrated resources, combination next stage will result in techno-technological then low-, medium- and high-technological resources improvement (if there is capacity and condition for the whole integration of educational, investment, research and techno-technological resources based on convergence of systems and institutions).

The levels of educational resources impact domain (D 2) are determined to solve management quality improvement tasks. Level 2.1 includes the following items: the diagnosis of the gap between the current and required competence of the personnel, innovative and creative competence in a researcher and designer. The following educational methods facilitate the fulfillment of the items (level 2.2): the development of the competence to lay down business tasks and to identify the structural elements of the project work considering its innovative character and competitiveness for external challenges; participation in mixed teams at engineering educational centers. All these measures enable to reach positive synergy of applied methods (level 2.3): identification rate improvement of personal preferences, their concurrence with project themes, resource complexity, tools of high-tech development efficiency control, multidisciplinary and cross-branch knowledge (Borovkov et al., 2018)

The research resources impact domain aims at improving the quality of innovation transformations efficiency management in an extended range of diversified processes and differentiated results – from modernization to high-tech targeted transformations. Considering the high-tech development we set the following objectives (3.1): to work out the model of knowledge management mechanism that serves as tools for training and self-training to improve competence. While solving the objectives other methods should be involved (3.2): re-engineering of business processes; benchmarking; early research-oriented education and management consulting. These methods result in a combination of educational and research resources (3.3): operative and accurate identification of external challenges to find out the ways for enterprise knowledge management improvement; the system of interactive training and studying the directions of enterprise high-tech industrial production.

The impact of investment resources (D 4) aims at the improvement of investment attractiveness through achieving targets (4.3) and through the well-known methods of financing, investment attractiveness estimation of business and assessment of investment efficiency (4.2) (Baev, 2017; Baev et al., 2019; Bogachev & Shershnev, 2017).

Graphically management function impact domain (D 5) presents the dome, superstructure that means non-equivalence of the determinant domain degree and main role of management functions while integrating the enterprise resources. The model under discussion enabled modernizing the method of consistent taxonomies used for taxonomy characteristics cycling (Ayvazyan & Mkhitaryan, 1998). To use the model, the correlation between the key knots A, B, C (as operators or high-tech development efficiency improvement integrators) with the knots D, E, F, which connect and provide diversified processes of the four main resources impact, should be made. Ключевой узел G при этом обозначает наивысшую степень интеграции всех ресурсов предприятия. The key knot G determines the highest degree of integration of all enterprise resources. The graph sections are connected with information and communication channels that exchange the specialized data between the integration mechanism elements in the enterprise high-tech development management system. The model explains and substantiates the closeness of the knots in detail, which means the extra-highest coefficient of their clustering. In other words the probability of diversified complementary resources major impact increases, making it possible to consider them as the determinants. The impact integration is identified with various educational, research, investment and techno-technological resources according to the corresponding indicators of high-tech development efficiency management quality.

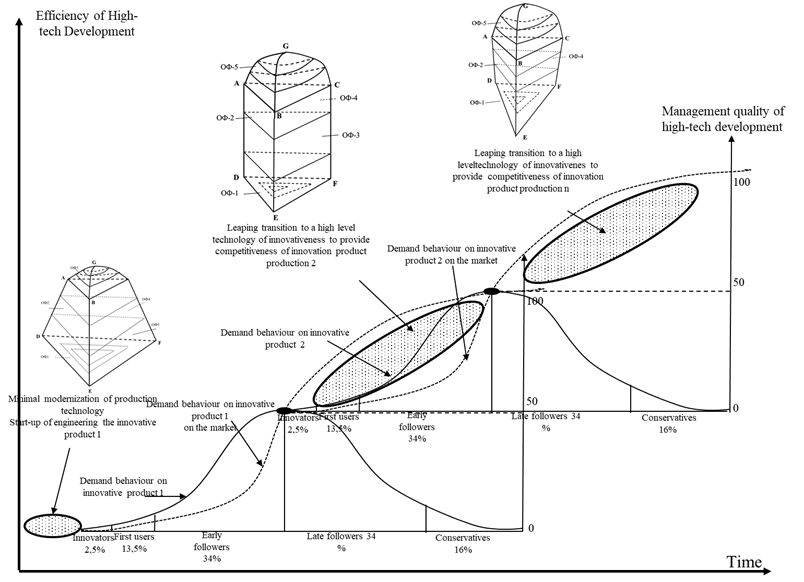

The impact domain of management functions is represented in the model «4D CR», it is supplemented with the possibilities of modeling the processes of innovative competence growth which provides the special functioning quality of management mechanism of resource integration and combination. We suggest supplementing the management theory with innovation development in the methods of engineering processes of combining the tools in the methodological model «4D CR» with the regulators of innovative enterprise competences in the Everett Rogers's innovation diffusion model (Rogers, 1983). The model implies the necessity to use general and specific management functions and quality indicators for their use, which are identified due to the corresponding stage and cycle of the high-tech development. Thus it provides the management quality over the leaping (the type of exhibitor or hyperbole) technological breakthrough that denotes launching the production of a new high-tech product described in the Figure

Our research puts forward the hypothesis of «4D CR» model greater impact as a result of combining models which aim at efficient engineering of transition from one innovative product to another during technological breakthrough identified in the Everett Rogers's innovation diffusion model where innovations are spread out in time (Rogers, 1983). We suggest combining with the possibilities of the «4D CR» model. The combination encourages the likelihood of a compromise between the innovation targets and the efficiency of developing and introducing a new product. The research proves that modernization and high-tech development demand the integration of different complementary resources sets. Thus a slight technology improvement only results in the production of low-tech products and engineering of management mechanism of resource integration and combination for a start-up to the leaping transition to the production of competitive innovation products.

Different configurations of the model «4D CR» in the Figure

Integration mechanism functioning leads to a greater waste of diversified resources then its engineering because the combination with the possibilities high-tech production competence adjustment in the model of innovation diffusion be Everett Rogers. Then criteria of compromise between opposite targets of efficiency and innovativeness are the condition for feedback of the mechanism shown by an arrow and a full line in Figure

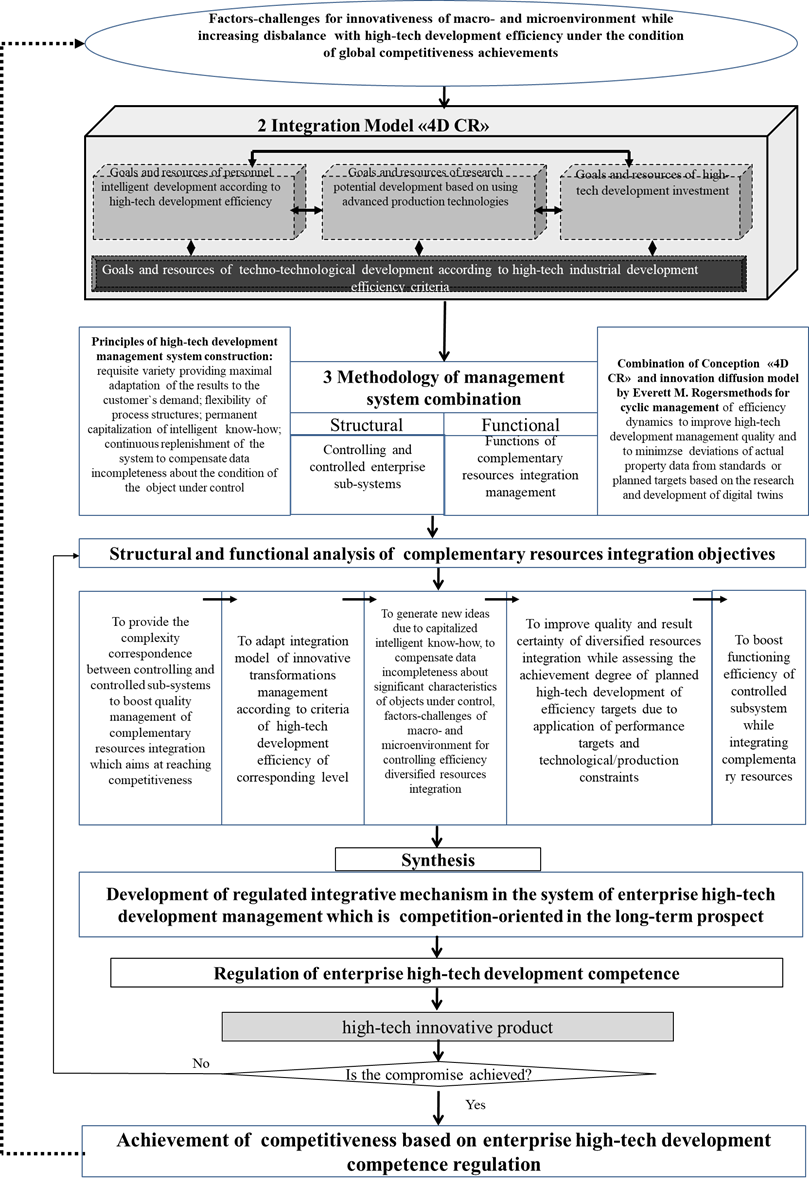

The suggested algorithmic scheme includes a range of elements: innovation factors of macro-and micro- environment, integration model «4D CR», principles of high-tech development control system construction, methodology of structural and functional system of high-tech development control, conception «4D CR» and cycliс control methods of the high-tech development efficiency, structural and functional analysis of integration for a set of resources and then synthesis, that is the engineering of management mechanism of resource integration and management methods combination (MRIMMMC) .

The algorithm focuses on controlling the resulting indicator – the system efficiency which is estimated by a timely production of a high-tech product. When the target of high-tech development (competitive modernization, low-, medium- and high-tech industrial production) is achieved the leaping transition to the innovative technology of a higher level takes place to provide competitiveness of industrial production. The algorithm of MRIM development and functioning, based on methodology of spatiotemporal integration of diversified resources and convergence of systems and institutions, enables to reach compromise between the targets of innovativeness and efficiency of high-tech development.

Conclusion

Thus, the suggested methodological combining of «4D CR» and the innovation diffusion model provided engineering the efficient integration mechanism «4D CR» and made it possible to improve the quality of control over complementary educational, research, investment and techno-technological resources. The functioning of the mechanism calls for the development and application of additional control functions which are identified by the type and the stage of the high-tech development. The hypothesis of high-tech transformations efficiency improvement can enhance management quality in the mechanism under discussion and methods of combining the model «4D CR» with the regulators of enterprise competence types in the model of innovation diffusion by Everett Rogers.

Spatiotemporal and convergence and integration methodology provide evolutionary and cyclic processes to achieve standard or peak level of system high-tech development efficiency. The integration of four resource types is defined as a critical factor for the balanced development of high-tech industrial production. The convergence approach to integrating and combining industrial enterprise key resources extends the range of applied management methods while organizing and developing high-tech industrial production. It guarantees the emergence of the system holding its elements behavior parameters in the range of possible high-tech development efficiency trajectory changes. The compromise between innovativeness and efficiency provides the competitiveness of the industrial enterprise in the long-term and short-term periods.

References

- Alabugin, A., Alykov, S., & Alabugina, R. (2016). Managing cooperation between business ano university: Quality assurance using sustainable development indicators from a knowledge management system. International confererence of education, Research and Innovation, 6938–6945.

- Alabugin, A. A., & Beregovaya, I. B. (2017). Aktual'nyye problemy upravleniya protsessami formirovaniya i razvitiya vysokotekhnologichnogo promyshlennogo proizvodstva pri perekhode k modeli poliresursnoy integratsii faktorov preobrazovaniy [Actual problems of managing the processes of formation and development of high-tech industrial production in the transition to a model of polyresource integration of transformation factors]. Creative economy, 6(11), 695–706.

- Andersen, V. D., Bitligo, R. R., & Johnson, S. R. (1989). Stability of adaptive systems. Moscow: Mir.

- Ayvazyan, S. A., & Mkhitaryan, V. S. (1998). Prikladnaya statistika i osnovy ekonometriki [Applied statistics and fundamentals of econometrics]. Moscow: UNITY.

- Baev, L. A., Dzenzelyuk, N. S., & Kochegarova, L. G. (2019). Otsenka kachestva sotsial'no-ekonomicheskogo razvitiya Chelyabinskoy oblasti [Assessment of the quality of social and economic development of the Chelyabinsk region]. Bulletin of the South Ural State University. Series: Economics and Management, 3(13), 14-22.

- Baev, L. A. (1992). Intensivnaya samoorganizatsiya ekonomicheskikh sistem : Kontseptsiya, teoriya, modeli [Intensive self-organization of economic systems. Concept, theory, models]. Chelyabinsk: Publishing house of ChSTU.

- Baev, L. A. (2017). Osnovy analiza investitsionnykh proyektov [Fundamentals of the analysis of investment projects]. Chelyabinsk: Publishing Center of SUSU.

- Berezansky, D. P., & Chulkov, A. K. (2017). Integration of project management methods and lean manufacturing tools with the quality management system. Quality Management, 5-6, 18-27.

- Bogachev, V. F., & Shershnev, V. V. (2017). Assessment of investment attractiveness and sustainability of the entrepreneurial structure. Economics and Entrepreneurship, 5-2(82), 619-621.

- Borovkov, A. I., Ryabov, Yu. A., Kukushkin, K. V., Maruseva, V. M., & Kulemin, V. Yu. (2019). Tsifrovyye dvoyniki i tsifrovaya transformatsiya predpriyatiy OPK [Digital twins and digital transformation of enterprises of the military-industrial complex]. Bulletin of the East Siberian open Academy, 32. http://vsoa.esrae.ru/206-1150

- Borovkov, A. I., Ryabov, Yu. A., & Maruseva, V. M. (2018). Novaya paradigma tsifrovogo proyektirovaniya i modelirovaniya global'no konkurentosposobnoy produktsii novogo pokoleniya [New paradigm of digital design and modeling of globally competitive products of a new generation. Digital production. Methods, ecosystems, technologies]. Moscow: Department of corporate training of the Moscow school of management SKOLKOVO. https://fea.ru/news/6721/

- Plotnikov, V. A. (2018). Tsifrovizatsiya proizvodstva: teoreticheskaya sushchnost' i perspektivy razvitiya v rossiyskoy ekonomike [Digitalization of production: theoretical essence and prospects of development in the Russian economy]. Bulletin of the Saint Petersburg state University of Economics, 4(112), 16-24.

- Rogers, E. M. (1983). Diffusion of innovations. New York: Free Press.

- Shibanov, K. S. (2019). Study of the features of lean production technology. Economy and Entrepreneurship, 1(109), 1045-1049.

- Smirnova, A. A., & Erokhina, E. V. (2019). Implementation of methods and techniques of total quality management. Eurasian Scientific Association, 4-5(51), 289-291.

- Tao, F. (2018). Digital twin-driven product design framework. International Journal of Production Research, 57, 1-19.

- Tarasov, I. V. (2018). Industriya 4.0: ponyatiye, kontseptsii, tendentsii razvitiya [Industry 4.0: notion, concepts, development trends]. Business strategies: analysis, forecast, management, 6(50), 57-63.

- Tolstykh, T. O., Gamidullaeva, L. A., & Shkarupeta, E. V. (2018). Key factors in the development of industrial enterprises in the context of digital production and industry 4.0. Economy in industry, 1(11), 11-19.

- West, T. D., & Blackburn, M. (2017). Is digital thread/Digital twin affordable? A systemic assessment of the Cost of Dod's latest Manhattan project. Procedia Computer Science, 114, 47-56.

- Zang V.-B. (1999). Synergetic Economics. Time and changes in nonlinear economic theory. Moscow: Mir.

Copyright information

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

About this article

Publication Date

16 April 2021

Article Doi

eBook ISBN

978-1-80296-104-1

Publisher

European Publisher

Volume

105

Print ISBN (optional)

-

Edition Number

1st Edition

Pages

1-1250

Subjects

Sustainable Development, Socio-Economic Systems, Competitiveness, Economy of Region, Human Development

Cite this article as:

Beregovaya, I., & Alabugin, A. (2021). Methodology For Integrating Resources And Combining Methods For Managing High-Tech Development. In E. Popov, V. Barkhatov, V. D. Pham, & D. Pletnev (Eds.), Competitiveness and the Development of Socio-Economic Systems, vol 105. European Proceedings of Social and Behavioural Sciences (pp. 426-437). European Publisher. https://doi.org/10.15405/epsbs.2021.04.47