Enhancing Power Generation Availability In Nigeria Using Combustible Waste As Energy Source For Off- Grid Applications

Abstract

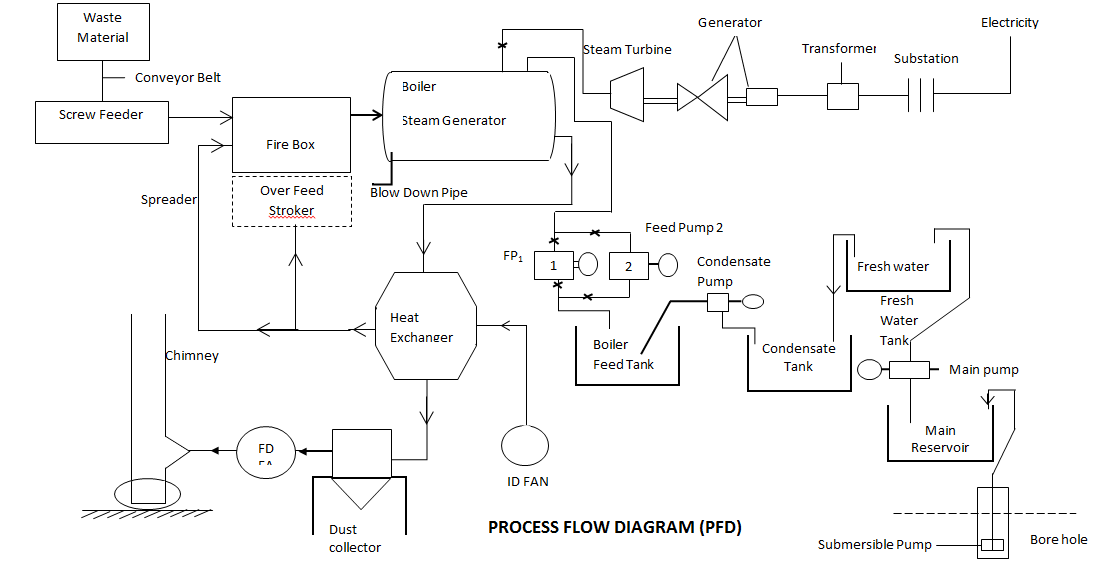

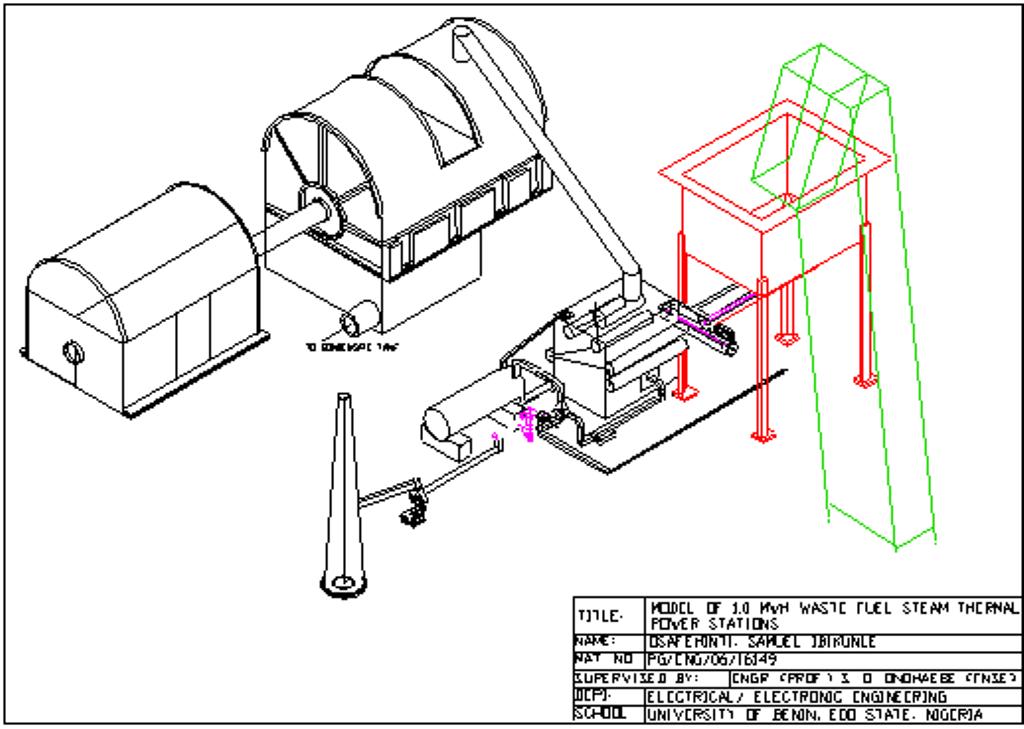

The application of combustible waste as energy source provides an alternative energy option to enhance electrical power generation for off-Grid applications. The integrated alternative energy sources identified are energy stored in metropolitan waste, energy stored in wood residue, and palm kernel residue. The framework studied the available quantities of these energy sources and developed a model to convert the energy options into electrical energy. The generating plant unit comprises Steam Generator, Steam Turbine, Steam Condenser, Pumps and Alternator with their ancillaries. The steam generator, a miniature low pressure externally fuel-fired water tube type consists of boiler, furnace, superheater, air-heater, stack, forced- and induced draught fans. The steam turbine is of the impulse- type whilst the condenser is a surface type. A software was also developed using visual Basic to run the Power Plant Model, the software utilized for the validation of boiler efficiency is Kane International calculator and for steam consumption in turbine whilst Katmar software was used for boiler efficiency. The simulated efficiency is 38.722 % and calculated result is 35.69 % for boiler performance whilst for steam turbine consumption is 3.22 kg/s and 3.123 kg/s. This model is suitable for off- Grid communities that are close to one another. It is recommended that colour coded waste bins be introduced at waste collection centres, incentives to farmers to bring waste to collection centres should be introduced and government should also invest in the production of the plant.

Keywords: Combustible wasteRenewable EnergyOff-Gridsimulationpower plant

Introduction

Energy is required in various forms to do useful work, it is necessary for the continuous improvement in the living standard in any society ( Ral, 2008). Energy sources (Coal, Crude oil, Natural gas, radioactive element) therefore have to be explored, developed and managed to enhance industrial process ( Sharma, 2007). The primary energy sources from which bulk electrical energy is produced in Nigeria are derived from fossil fuel which are limited in reserve, depleting and non-renewable. To sustain the increasing energy demand, the need therefore arises to explore non depleting sources of renewable energy, fuel wood renewable energy reserve is approximately 13,071,464 hectares in Nigeria ( Sambo, 2009) An overview of energy conversion principle is discussed whilst waste to power energy conversion strategy is considered in detail. The controlled combustion of waste in furnace converts the stored energy to produce steam required to drive a steam turbine ( Nag, 2008).

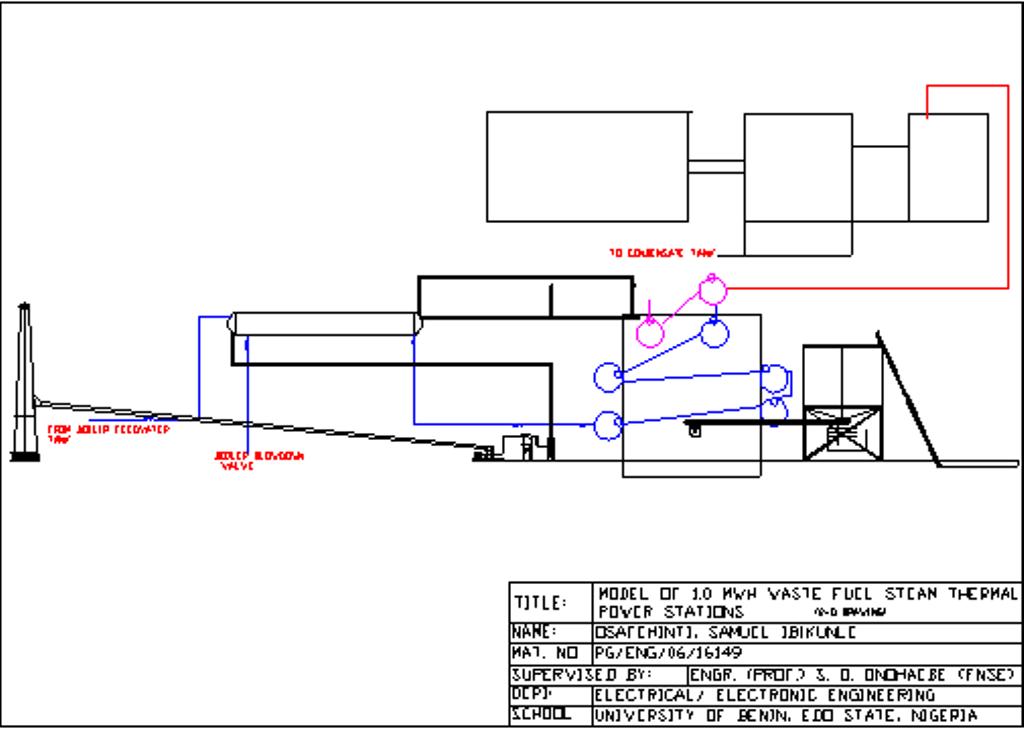

Model OF1.0MW steam power plant

The water tube is designed with inlet feed water at 152 oC/5 bar, discharged steam conditions at 300 oC/15 bar at turbine inlet with steam flow rate at 3.23Kg/s at 1.06 factor of evaporation and flue gas conditioned at 7.74kgS -1/160.8 oC at air heater outlet. The surface steam condenser requires 713000.85kg at cooling water per hour for condensate to maintain the exit water temperature at 440 oC (see Table

Problem Statement

The Electrical power supply in Nigeria is characterized with epileptic Nature, poor power quality, insufficient supply and do not accommodate the off-grid communities. The need arise to make energy available in the off grid settlement. Energy stored in waste has been identified and harnessed in this research.

Research Questions

Does applying combustible waste as energy source could enhance power generation for off- grid utilization?

Purpose of the Study

Aim and objectives

The aim of this work is to apply combustible waste as energy source to enhance power generation for off- grid utilization.

The objectives of this research are:

Identify and determine the quantity of combustible waste available and suitable as energy source in Ondo and Edo states.

Identify and develop a technology to harness this energy.

Evaluate the cost of deploying this source of energy option.

Develop a model for steam generating plant using combustible waste, wood and palm kernel residue as fuel.

Research Methods

The methodology adopted in this study is as follow;

Collection of data

Data collection on the quantity of combustible waste used as fuel in this research are classified under three headings; wood waste, (saw dust and off cut in saw mill) Oil palm residue (fibre and shell) and combustible component of house hold waste (paper, leaves). Data collected from states under review are average waste generated per person. Sample of waste were measured and classified by component ( Igbinomwanhia, 2012) to determine percentage composition usable as fuel in power plant.

Wood residue generated by the sawmill operation was evaluated. Palm residues were obtained based on the estimated area under oil palm in different production systems. Data collections were on the sport assessment, physical measurement, visit to host oil palm industryand ministry of agriculture and natural resources in the states under review.

Findings

This research is concerned with the development of an innovative technology of waste to energy generation and the following were findings of the study;

Wood waste and saw dust are exposed to direct open air combustion of no economic value and this often causes environmental pollution. When put in use as fuel for energy generation in power plants, it will reduce dependency on crude oil and its allied products and also add value to the waste.

Metropolitan wastes are lumped together with no provision for separation at the collection centre thereby creating challenges in waste disposal mechanism as they always occupy very large space. Putting the waste in use for energy generation will help in reclaiming land and reducing health hazard associated with improper waste disposals.

The existing power generation plants in the country predominantly use fossil fuel which is expensive, depleting and it is not also environmental friendly. A major setback in Energy generation will occur in the event of shortage of this fuel.

The estimated calorific value of wood residue, combustible waste and palm kennel residue are 160,868 kJ/kg and 188,880 kJ/kg respectively.

The mass of wood residue generated in Ondo State is 1, 064,394kg per day; this quantity is capable of running the designed 1.0 MW Power Plant for 3 years. In order words, running 3 Units of 1.0 MW Power Plant for a year. Likewise in Edo State, 957, 427kg of wood waste residue is generated per day and this is capable of running 1.0 MW Power Plant for 3 year or 3 Units of 1.0 MW for a year.

The combustible waste generated in Ondo State is 376,440 kg per day, this can sustain 1.0 MW-h for 1 year, whilst in Edo State, the combustible residue generated, 360,228kgper day is capable of running 1.0 MW Power Plant for a year.

The Palm kernel residue generated in Ondo State is 92, 707.5 tons/year; this quantity of fuel is capable of running 0.95 MW Power Plant for a year, but the palm kernel residue in Edo State of 114626 tons/year is capable of running 1.0 MW electrical Power Plant for a year.

The generating plant can utilize all the wastes under study as fuel. And (10) ten megawatts can be generated from both states.

From the findings, the generating Plant is feasible in Ondo State using wood residue and combustible waste whilst in Edo State, the electrical energy generating plant is feasible using wood residue, combustible residue and palm kernel residue.

Conclusion

A computer software using visual basic was developed to simulate each module of the model; furnace design, superheater design, airheater design, chimney, draft design, and steam turbine to determine boiler efficiency, load factor and steam consumption. The result was validated using two other software kane international engineering calculator for boiler efficiency and steam turbine consumption calculator (katner software) for steam consumption.

Mass of combustible waste required to run the power plant per year with due consideration to the calorific value was estimated.

Validation of result

The software utilize for the validation Of result are Boiler Efficiency (kane international engineering calculator) and The steam turbine consumption calculator (Sugar engineeering library/katmar software):

Boiler Efficiency

Software Result 38.722%

Calculated Result 35.69%

Steam consumption for design power 1.5MW in Turbine

Software Result 3.14kg/s

Calculated Result 3.123kg/s

Steam consumption for rated power 1.0MW in turbine

Simulated result 2.094kg/s

Acknowledgments

Tertiary Education Trust Fund (Tetfund Nigeria).

References

- Igbinomwanhia, D. I. (2012). Characteristic of Commercial Solid Waste in Benin metropolis Nigeria. Journal of Emerging Trends in Engineering and Applied Science, 3(5), 834-838.

- Nag, P. K. (2008). Power Plant Engineering (Second Edition). New Delhi: Tata-McGraw-Hill Publishing Company Ltd.

- Ral, O. D. (2008). Non-Conventional Energy Sources (Fourth Edition). New Delhi: Khanna Publishers.

- Sambo, A. S. (2009). Strategic Development in Renewable Energy in Nigeria. International Association of Energy Economic.

- Sharma, P. C. (2007). Power Plant Engineering (Eighth Edition). New Delhi: K. Kataria & Son.

Copyright information

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

About this article

Publication Date

30 March 2020

Article Doi

eBook ISBN

978-1-80296-080-8

Publisher

European Publisher

Volume

81

Print ISBN (optional)

-

Edition Number

1st Edition

Pages

1-839

Subjects

Business, innovation, sustainability, development studies

Cite this article as:

Osafehinti, S. I. (2020). Enhancing Power Generation Availability In Nigeria Using Combustible Waste As Energy Source For Off- Grid Applications. In N. Baba Rahim (Ed.), Multidisciplinary Research as Agent of Change for Industrial Revolution 4.0, vol 81. European Proceedings of Social and Behavioural Sciences (pp. 664-669). European Publisher. https://doi.org/10.15405/epsbs.2020.03.03.77